Project introduction

United Utilities worked alongside tech innovators ChangeMaker 3D, Manchester Metropolitan University PrintCity and Scottish Water on a project to develop 3D printed infrastructure and components for the water sector.

The project received funding from Ofwat’s Water Breakthrough Challenge, a £200 million Innovation Fund to grow the water sector’s capacity to innovate, enabling it to better meet the evolving needs of customers, society and the environment.

This innovative project has resulted in multiple firsts for the UK water industry, whilst demonstrating significant carbon, cost and labour savings.

The learnings from the project are being disseminated to the entire sector with Spring Innovation as the knowledge-sharing partner.

Ofwat innovation themes

New ways of conducting core activities

New approaches and options for the construction and maintenance of assets.

Responding and adapting to climate change

Replacement of common construction and manufacturing materials with reduced carbon and recycled alternatives.

Delivering long-term operational resilience

Efficient and fast response to required maintenance, operation and construction.

Ofwat innovation fundWork package one

3D Concrete Printing - An ambitious project which is the result of three years of development and research.

United Utilities worked alongside tech innovators ChangeMaker 3D to develop a project that was a first for the water industry.

A 3D concrete printing hub was set up at United Utilities’ Wigan Wastewater Treatment Works to print a range of equipment including combined sewer overflow (CSO) chambers.

The assets for use in the sector are being printed in a matter of hours compared to the several days it would take using traditional methods. The printing process is financially and environmentally efficient, with significant carbon savings.

Small items can be printed in as a little as 45 minutes, and the innovative approach also delivers safety benefits by reducing the requirement to work at height or in confined spaces.

Work package two

3D Polymer Printing - United Utilities worked alongside PrintCity, a 3D manufacturing facility based within Manchester Metropolitan University.

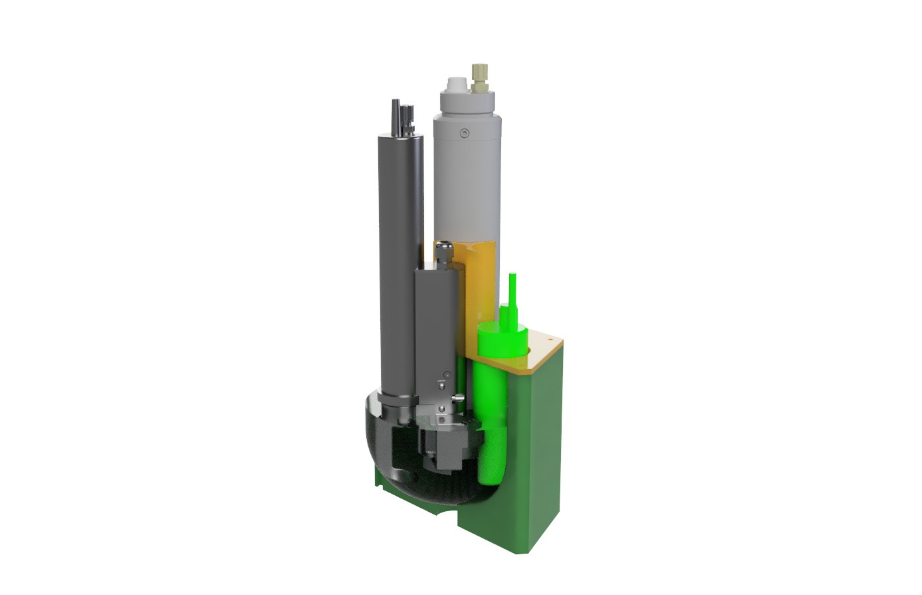

This work package proved the viability of polymer 3D printing for the water industry, with a focus on replacement parts including a wastewater jet nozzle, CCTV skid plate, trough for water monitoring instruments and laboratory equipment.

Starting with research by PrintCity to develop 3D scanning models, the project progressed to create replacement parts through 3D scanning, computer aided design (CAD) and 3D polymer printing that are now successfully used across United Utility and Scottish Water sites following rigorous testing and trials.

Again achieving a first for the UK water industry, the 3D printing of polymer replacement parts helps manage and upgrade key equipment whilst addressing challenges around environmental concerns, equipment availability, delivery times and rising costs.

Work package three

In this phase of the project United Utilities demonstrated the carbon reduction and social value benefits this innovative technology delivers. Work package 3 reflected on how 3D-printed concrete structures reduce reliance on carbon-heavy materials, using alternatives that support United Utilities’ Net Zero goals while building a more sustainable future for infrastructure.

In addition to carbon savings, the fast and precise 3D printing process enables efficient construction and maintenance, minimising project timelines and reducing the impact on resources and operations. This streamlined approach ensures the water infrastructure can meet demand for both planned improvements and urgent repairs with lower environmental impact.

The project supported a new skills market by introducing a larger need for digital construction skills in the industry, helping to expand employment opportunities with a workforce aligned with United Utilities’ social value goals. By fostering new talent, the Printfrastructure project promotes a greener approach to construction, encouraging career growth in sustainable and digital fields within the UK.

Work package four

Building on its organic growth and success, this phase of the project moves towards commercialisation bringing scalable 3D printing solutions to the wider water industry.

As the demand and viability has grown, printing facilities have demonstrated flexibility by operating both off site and on location, reducing costs and logistical constraints. This technology provides substantial savings for the water industry by cutting down on materials, time, and overall project expenses.

The project has opened new partnerships across major UK sectors including rail and highways, joining United Utilities, ChangeMaker 3D, and PrintCity with stakeholders working towards a connected, lower-carbon infrastructure. By fostering cross-industry collaboration, the project supports a more sustainable, greener future in the UK.

The Printfrastructure project is enabling the efficient production of essential infrastructure components, such as combined sewer overflow (CSO) chambers. These structures are vital for reducing spills, helping water companies manage public relations and avoid fines, while enhancing operational efficiency. Through commercialisation, Printfrastructure is paving the way for broader, impactful change in both infrastructure and environmental responsibility.

Work package five

The final phase of the Printfrastructure project centres on disseminating the learnings, with Spring Innovation as the knowledge-sharing partner.

United Utilities will share best practices, demonstrating how 3D printing technology can transform infrastructure construction and maintenance with significant carbon, cost, and time savings. This outreach will also emphasise how Printfrastructure supports sustainability goals, showing how the entire sector can adopt and benefit from this technology.

To maximise impact, the project team will engage with industry bodies, stakeholders and policymakers, via events, surgery sessions, and case studies which will be hosted on the Spring Platform, ensuring that the lessons learned contribute to broader infrastructure innovation across the sector. By hosting workshops, publishing reports, and presenting case studies, United Utilities aims to inspire other organisations not only within the sector, but across other major UK industries to explore 3D printing applications in their own operations.

This dissemination effort is essential to ensuring that the project’s pioneering work inspires a connected, lower-carbon future across the UK.

Project partners

-

ChangeMaker 3D are designers, consultants and manufacturers in 3D mortar printing, helping to build greener solutions to the world’s most pressing issues.

ChangeMaker 3D’s role within the Printfrastructure project involved the innovation and delivery of the concrete printing aspect to the project, including collaboration on the opening of a 3D concrete printing hub at United Utilities’ Wigan Wastewater Treatment Works in June 2024, and the construction of combined sewer overflow chambers and Industrial Emissions Directive containment walls.

-

PrintCity MMU is a unique digital manufacturing facility based in the industrial city of Manchester – England with an emphasis on 3D additive manufacturing.

Responsible for the polymer printing aspects of the project, PrintCity MMU delivered replacement assets including a wastewater jet nozzle, CCTV skid plate and trough for water monitoring instruments which are now used by United Utilities in everyday operations, following rigorous testing and trials.

-

Scottish Water proudly deliver Scotland's water and waste water services to over 2.6 million homes and more than 150,000 businesses.

Scottish Water played an integral role within the Printfrastructure project by offering resources and use cases for the testing of the products including collaborative research, feasibility studies and rigorous testing on site and in laboratory settings. This further demonstrated the viability of the project as a low-carbon scalable solution.

-

Spring is the innovation centre of excellence for the Water sector, supported by all the water companies across the UK and Ireland as well as the supply chain and academia.

Spring delivered the knowledge- sharing aspects to the Printfrastructure project including dissemination events, hosting case studies on its platform, and creating knowledge-sharing resources that align to wider-sector and regulatory best practice with the ambition of removing duplication and creating widespread progression throughout the entire UK water industry.

Further resources

Spring platform

Head to the Spring Platform to find all knowledge-sharing assets related to the Printfrastructure project.

The platform requires an account but is free to join. Here you will find case studies, recorded events exploring the project, technical drawings and more.

Changemaker 3D YouTube

Changemaker 3D’s YouTube channel contains a range of videos further exploring the project and 3D printing techniques involved.

From information on Ofwat funding, to live on site demos and even videos highlighting the water industry firsts that were achieved, it’s well worth a visit.